Complete solution for

Inventory Management

Boost your business revenue and efficiencies while mitigating risk and lowering your operational costs

Smart Solutions for Inventory Management

Automated alerts

Receive timely notifications for low stock levels to prevent stockouts and maintain product availability.

Cost reduction

Optimize stock levels to reduce carrying costs and minimize waste, directly enhancing profitability.

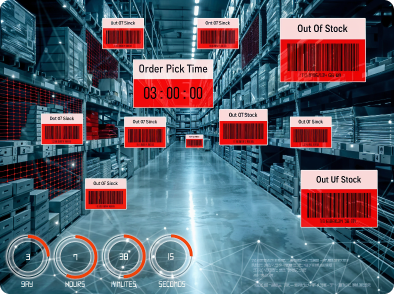

1CA built-in Advanced Inventory Management

Optimize Your Inventory Operations with Real-Time Updates, Automated Replenishment dashboards, and Centralized User-Based Control in our Unified Platform.

Real-time

Synchronization

1CA’s Advanced Inventory Management keeps your inventory data synchronized across all marketplaces, stores, 3PLs & warehouses. This empowers 1CA users to maximize accuracy, minimize errors & strengthen their brand presence.

Forecasting &

Demand Planning

Empowers businesses to anticipate market trends and optimize inventory levels, ensuring customer demand is met efficiently and effectively.

Unified

Platform

End-to-End eCommerce tools unified in One Single Platform helps brands and retailers maximize efficiency, accuracy, and profitability.

Streamlined

Multi-Channel Selling

Built-in Marketplaces Integrations empower 1CA users to effortlessly expand their reach and sell across hundreds of marketplaces with ease.

Built-in Advanced Inventory Management

OneChannelAdmin helps brands and retailers streamline their inventory management operations using 1CA’s built-in Advanced Inventory Management.

- User-based access: Manage inventory securely with customizable user permissions, allowing tailored access and control for different team members.

- Automated and optimized workflows: Save time and reduce errors with automated inventory processes that streamline replenishment, stock allocation, and order fulfillment.

- Highly configurable dashboards, workflows, and reports: Personalize inventory views and workflows with flexible dashboards and generate real-time, actionable reports tailored to business needs.

- Real-time synchronisation with unlimited marketplaces, partners, and systems:Ensure accurate and up-to-date inventory data across all sales channels and partners with seamless real-time syncing.

- User-friendly interface:Simplify complex inventory management tasks with the most intuitive and easy-to-use system designed to enhance operational efficiency for all users.

Bundle Products for Efficient Inventory Management

- Revenue Enhancement: Boost sales by creating bundles without increasing inventory.

- Simplified Management: Treat bundles as single units, reducing waste and effectively managing slow-moving items.

- Ready-to-Ship Kits: Improve customer experience with pre- assembled products for faster fulfillment.

- Attribute Monitoring:Track characteristics like size and color to prevent overselling and ensure timely restocking.

- Data-Driven Decisions:Use analytics to forecast demand and refine bundling strategies for informed inventory management.

Simplified Supply Chain and Storage

- Unlimited warehouse and 3PL integration: Seamlessly connect with multiple warehouses and 3PLs to optimize storage and fulfillment strategies across diverse locations and sales channels

- Vendor and supplier management: Easily integrate and manage an unlimited number of vendors and suppliers to streamline procurement, reduce delays, and ensure steady product availability.

- Real-time shipment tracking: Monitor and track shipments in real-time from order placement to delivery, ensuring visibility and transparency throughout the entire supply chain.

- Cross-channel inventory visibility:Gain a unified view of inventory levels across all warehouses, suppliers, and 3PLs to minimize stockouts and overstock situation

- Automated reordering and stock alerts:Set automated reordering rules and receive proactive stock alerts, ensuring that businesses can maintain optimal stock levels across all integrated locations.

- Key Performance metrics and user-based dashboards:Monitor essential inventory KPIs with customizable, user-based dashboards that provide real-time insights into stock levels, order fulfillment, and supply chain performance.

- 1CA built-in Rate shopping tools:Leverage built-in rate shopping tools to compare shipping costs across carriers, helping businesses reduce shipping expenses and maximize profitability with the best shipping rates available.

Strategic Inventory Nexus

1CA’s Advanced Inventory Management centralizes, automates, and simplifies multi-sales channels management

Multi-Channel Sales Management

Automated Vendor

Feeds

Order Fulfillment

Optimization

Customizable Reports

Integrated E-commerce Solutions

Barcode Scanning

Historical Data Analysis

Automated Stock Alerts

Accurate Forecasting

Our goal is to boost your business revenue and efficiencies while mitigating risk and lowering your operational costs.

Real-time synchronization with channels and platforms

Real-time sync with marketplaces includes inventory syncing, order syncing, automated stock level updates, multi-channel sales management, and marketplace-specific features such as automatic repricing and feedback management.

Real-time sync with marketing channels automatic syncing of ad campaigns, real-time adjustments or pausing of campaigns based on inventory levels, tracking of campaign performance, monitoring of customer behavior across multiple channels, and automated bid adjustments based on inventory levels, ensuring maximum ROI while preventing overspending on out-of-stock products.

Real-time sync with brick-and-mortar stores POS marketplaces, marketing channels, and product data offers benefits such as scalabipty, competitive advantage, improved data security, faster time-to-market, improved partner relationships, improved customer service, and reduced risk of errors, overselpng, and stockouts, integration with popular POS systems.

Real-time sync with social media channels includes product tagging, social commerce integration, real-time social media monitoring, customer engagement tracking, and automated posting of product updates and promotions based on inventory levels.

Real-time sync with carts includes inventory syncing, cart syncing, real-time stock level updates, cart abandonment tracking, and integration with popular E-commerce platforms.

Real-time sync with webstores includes inventory syncing, order syncing, automated stock level updates, product information syncing, integration with popular webstore platforms, and real-time sales and inventory reporting.

Real-time sync with vendor software feature allows users to synchronize inventory data with their vendors in real-time, ensuring accurate and up-to-date inventory levels. It automates inventory management processes, reducing the time and effort required to maintain inventory levels.

Product Advertising Campaigns (PACs) on all marketplaces

Easily track inventory at every stage of the supply chain, from procurement and production to final sale. Monitor stock levels, track stock movements, and optimize processes for greater efficiency and profitability.

Centralized inventory management system allows them to to manage all their inventory in one place, providing a comprehensive view of stock levels across all marketplaces like Amazon, Ebay, Walmart, and more. This helps brands and retailers make informed decisions on inventory replenishment and reduce stockouts.

Automatic stock alerts will get notified when inventory levels reach a certain threshold, so you can restock before running out of stock.

Accurate forecasting predicts future inventory needs and plans accordingly to avoid stockouts and excess inventory.

Automated replenishment can be set up to automatically reorder inventory when stock levels reach a certain threshold, reducing the risk of stockouts and ensuring that inventory levels are always optimal.

Generate Customizable Reports to gain insights into sales trends, product performance, and inventory levels.

Barcode scanning technology to quickly and accurately update inventory levels, reduce errors, increase efficiency, and integrate with other systems for streamlined operations.

User permissions, ensuring only authorized users can make changes to inventory levels.

Historical track inventory data, allows businesses to analyze sales trends and predict future demand.

Efficiently manage your inventory with optimized kit, bundle, variations and attribute management.

Create new products by bundling existing items together, businesses can create new products without having to purchase additional inventory. To enable them to expand product offerings and increase revenue.

Bundle products simplify inventory management by allowing for easy management of multiple items as a single unit, reducing errors and streamlining the process.

Effective inventory management that includes bundling slow-moving inventory with fast-moving items can improve inventory utilization, minimize waste, and ultimately reduce costs, leading to an improved bottom line.

Streamline order fulfillment Kits can be created in advance and stocked in inventory, allowing businesses to fulfill orders faster and more efficiently. This improves the overall customer experience and reduces the risk of errors.

Efficiently track inventory levels for each product attribute, such as size or color, to optimize inventory management and prevent overselling with ease.

Simplify inventory management process by grouping items with the same product variations together and managing inventory levels for each product variation as a single item, rather than tracking the inventory levels of each individual item separately.Manage multiple warehouses and 3PL’s

Get deeper insights into Customer Behavior Accurate inventory tracking with centrapzed inventory management, businesses can track inventory levels and movements across multiple warehouses in real-time. This ensures that inventory data is accurate and up-to-date, enabpng to make better decisions about procurement, production, and fulfillment.

Track inventory levels by managing inventory across multiple locations, to get a real-time view of inventory levels.This helps make informed decisions about purchasing and restocking inventory.

Optimize inventory storage by tracking inventory levels across multiple locations, businesses can optimize inventory storage and reduce the risk of stockouts. They can allocate inventory to the locations where it is most needed, ensuring that they always have the right inventory on hand.

Streampne order fulfillment by leveraging multiple inventory locations to manage inventory, allowing businesses to efficiently ship products from the nearest location to the customer, leading to reduced shipping times and an enhanced customer experience.

Reduced shipping costs by strategically locating inventory in multiple warehouses or using 3PL’s, businesses can reduce shipping costs and transit times for customers.

Enhanced Visibility and Control all warehouses and 3PLs are managed in one place, for better visibipty and control over their supply chain. This includes tracking inventory levels, monitoring order status, and managing transportation and logistics operations.

Automated inventory and pricning feeds

Automate inventory updates by setting up vendor feeds,to automate the process of updating inventory levels. When a vendor updates their product information, NetSuite’s inventory management software automatically updates the inventory levels in the system.

Automated inventory and pricing feeds improve accuracy by reducing human error, ensuring real-time inventory data, minimizing the risk of stockouts or overstocking, and helping businesses set the right prices, leading to increased sales and improved profits.

Reduce manual effort by automated inventory and pricing updates through data feeds can improve efficiency, reduce errors, and ultimately lead to improved productivity and profitability.

Improve accuracy with automated inventory updates ensure that inventory levels are accurate and up-to-date, which can help businesses avoid stockouts and overselpng.

Improve collaboration by sharing data with vendors through vendor feeds, businesses can improve collaboration and communication, which can lead to better business relationships and more favorable terms.